content removed.

63-79 Differential Yoke inspection

21 - 40 of 42 Posts

Joined

·

18 Posts

thanks for your time, you've been a big help... one more question please. How much endplay should I accept before I go back to the place that put a rear in my car for $2500, and tell them they goofed? I put 1k to 1.5k miles on it since it was done in aug, 07.

Joined

·

148 Posts

Gary,

How do you feel about button welds on tips of the side yokes and ground down on side yokes that are too short and the person doesn't want to spend the cash t fix it correctly?

How do you feel about button welds on tips of the side yokes and ground down on side yokes that are too short and the person doesn't want to spend the cash t fix it correctly?

Joined

·

3,827 Posts

Hard for me to comment on another job as I don't know how it was done. I can guess, and that would be it was a stock setup. All the diff I do I have to grindthe yokes faces to set the endplay to between .005-.010" max. With a stock posi setup .030 is about what you will see. As Mike said they can be all over the place and I've had some new and rebuilt yoke come in that were not machines correctly and were way off. In your case I would ask the guys who did the job how they did it and what the spec's were on it.thanks for your time, you've been a big help... one more question please. How much endplay should I accept before I go back to the place that put a rear in my car for $2500, and tell them they goofed? I put 1k to 1.5k miles on it since it was done in aug, 07.

Joined

·

3,827 Posts

Ryan,Gary,

How do you feel about button welds on tips of the side yokes and ground down on side yokes that are too short and the person doesn't want to spend the cash t fix it correctly?

I have not done that but have heard of guys doing it. If the weld is hard and neatly done then it would work. The spline portion doesn't matter on the end of the yoke. Me, I prefer to replace the yoke and fit them but again it has worked in the past.

What I have not seen is a good fix for the housing once the yke grinds it down into the seal, anyone know of one?

Joined

·

231 Posts

gtr1999; What I have not seen is a good fix for the housing once the yke grinds it down into the seal said:That's my next project as soon as I get caught up on other work.

Mike

Joined

·

3,827 Posts

The only thing I can think of is to setup the housing in a mill and bore the side and install a steel sleeve. Not sure of the wall thickness in that area and the radius. It might be less costly finding a used diff, that's what I've done.

The one in my 75 was ground pretty good but I was able to reuse it with no leaks. I was watching it to see but that's the one Kevin took care of for me:thud:

The one in my 75 was ground pretty good but I was able to reuse it with no leaks. I was watching it to see but that's the one Kevin took care of for me:thud:

Joined

·

3,827 Posts

What year is the diff? The later C3's (75-79) had bad side yokes,they were not hardened. .125" is an indication of several possible areas.

1- worn yoke

2- posi setup

3-cross shaft wear in the case

4 some vendor's rebuild:laughing: Yes, some people have been told .100 is normal- it is not.

1- worn yoke

2- posi setup

3-cross shaft wear in the case

4 some vendor's rebuild:laughing: Yes, some people have been told .100 is normal- it is not.

63-79 differential inspection

differential is 1971,when i bought the car some years ago after driving the car approx 400 miles home the diff started to groan on lock when reversing,oil was low,topped it up with gm oil and additive didnt give any problems since just the excessive play in the yolks

differential is 1971,when i bought the car some years ago after driving the car approx 400 miles home the diff started to groan on lock when reversing,oil was low,topped it up with gm oil and additive didnt give any problems since just the excessive play in the yolks

Joined

·

3,827 Posts

I'm doing a 72 diff now and the yokes are original. I reconditioned them and here's a cool tool my buddy had. Checking the original yoke hardness. Still good. I have been able to reuse many original yokes from the 60's - 73. The later yokes are not as good and softer.

![Image]()

![Image]()

Joined

·

358 Posts

Question for us n00bs

Gary,

I have a 79 and had to move her from my garage to another garage for storage. She drove very well and I didnt hear any whining coming from the diff apart from a little when in reverse. To be honest, Im not sure if it was diff or trans noise.

Anyway, what is the procedure for testing endplay/movement etc with diff still in the car or is it something that can only really be checked with the unit removed?

I will be doing a body off but would like to drive it a little first just to get some idea of what I need to do with regards the engine, trans and diff.

Thanks in advance.

Gary,

I have a 79 and had to move her from my garage to another garage for storage. She drove very well and I didnt hear any whining coming from the diff apart from a little when in reverse. To be honest, Im not sure if it was diff or trans noise.

Anyway, what is the procedure for testing endplay/movement etc with diff still in the car or is it something that can only really be checked with the unit removed?

I will be doing a body off but would like to drive it a little first just to get some idea of what I need to do with regards the engine, trans and diff.

Thanks in advance.

Joined

·

3,827 Posts

You can check them in the car to a degree. Remove the 1/2 shafts and mount an indicator against the yoke to check the endplay. However endplay is usually a combination of yoke wear,posi setup and posi cross shaft play. Replacing the yokes alone in most cases is not enough. A lot of rebuilders are sloppy and don't get the clutches setup as they should be, so you really have to get the unit apart to get an accurate check.

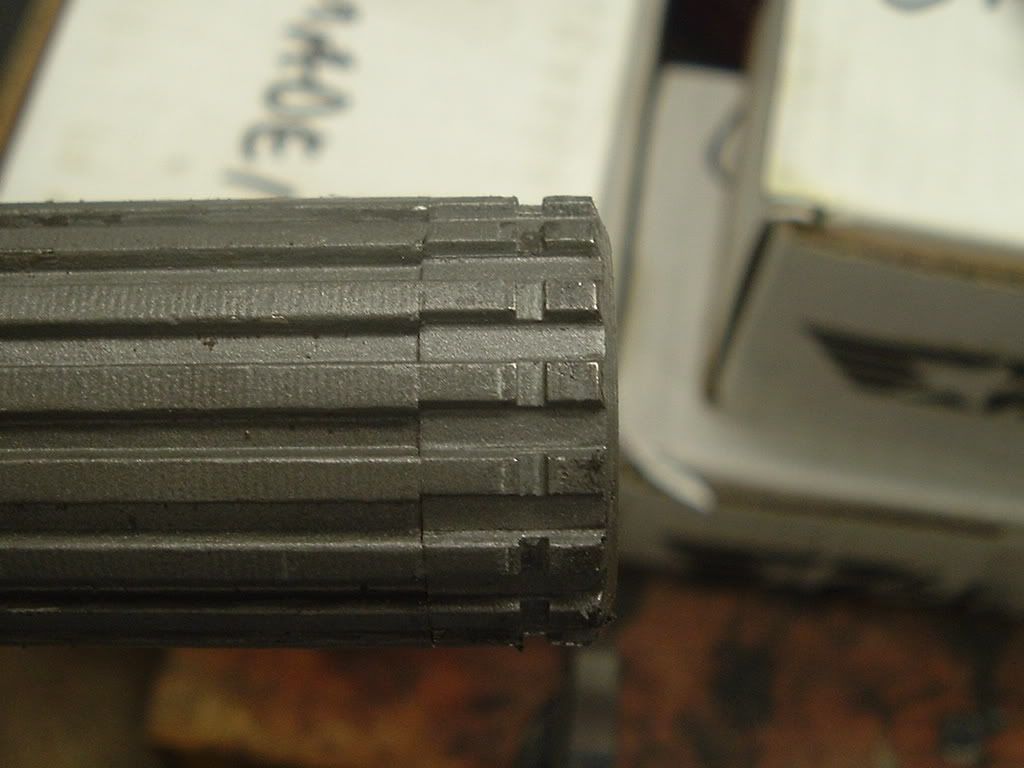

Tips...TIPS?!! Where are my tips?!:huh:Here something to check with rebuilt yokes, and I'll post this on the rebuild post as well.

I had some come in that were rebuild poorly and the splines didn't line up. Now most of the time this doesn't happen but if you're like me and buy parts to use in a year or more then look at them when you get them.

Here is the end of the yoke. You can see the tip is not aligned and this would not fit in the side gear unless it was hammered in. Maybe some do that as well:surprised

![Image]()

Oh! There they are...still inside the differential!?:WTF

Just pulled my '78 rear end down for cleaning and 6-Link design & fab, and it seams that both of my yolk spindles are broken. It appears (from the pic you posted above) that the rod joining the main shaft of the yolk and the tip has snapped, leaving the tips inside the differential, still sitting in the splines, while allowing me to pull the yolks out of the diff. with no tools at! I don't know if these were rebuilt or not, also didn't know that the tip was a seperate piece.

So it looks like a the very least new spindles are in order, and I'm also in the middle of fabricating a 6-Link (the reason I pulled the rear end in the first place.)

With the 6-Link, I'm planning on floating the spindles, (no snap ring), but how much of the spindle gets shaved for this set up?

Have you heard of the tips snapping like this? I had the rear end rebuilt shortly after I got the car in the early 90's, so I don't know if this is a result of poor workmanship, cheap parts or just what happens to a daily driver over a period of 10 -12 years, (stopped driving it in 2002 when I moved to las Vegas from California.)

Joined

·

3,827 Posts

The original yokes were not machined and spliced like the rebuilts. Properly done you shouldn't have a problem. Yours sound pretty bad and could be like the Junk I found in Curby's diff a couple of months ago. They were hollow and sheared off.

If you're going to beat up your car and have power I would build a diff like I did for Curby.

http://www.digitalcorvettes.com/forums/showthread.php?t=131265&highlight=diff

http://www.digitalcorvettes.com/forums/showthread.php?t=139114&highlight=diff

If you're going to beat up your car and have power I would build a diff like I did for Curby.

http://www.digitalcorvettes.com/forums/showthread.php?t=131265&highlight=diff

http://www.digitalcorvettes.com/forums/showthread.php?t=139114&highlight=diff

Yeah, eventually I'm gonna want to add some power.

The weird thing is, the breaks look clean, (unlike the ones shown in the links you just posted. The only place where it looks like a break occured is in the center of the spindle (1/2" dia.), the section around the center where the splines are cut looks machined, not broken. If it were not for the obvious metal shearing that took place in the middle, you'd think the spindles were machine that way, (makes me wonder if these were cheap rebuilds).

EDIT: So they sometimes "splice" these things together? THAT's what it looks like I've got, it's too clean to have been a complete shear. Why do they "splice"? Do they take spindles with damaged tips and cut them of and splice new ones on?

So, I'm hoping that the tips haven't done too much damage to the (rod that holds the spider gears...can't remember exactly what that's called).

Anyway, I think I have the mechanical apptitude to rebuild myself, I'll have to follow your threads.

The outer spindle bearings, seals, etc. all seem fine, although there is a little more play in the drivers side bearing than the passanger side, no play in the pinion shaft, and no excessive play between the gear and pinion, (as far as I can tell by just rotating the pinion shaft by hand)

What do you think I'm looking at money wise (ball park), for

a) minimal investment, just replacing broken spindles (hopefully nothing else is broken, but won't know until I pull the cover).

b) full blown heavy duty rebuild, including new clutch packs, new gear and pinion, HD spindles, etc.

Would it be cheaper to buy a complete unit from say Duntov, rebuild myself (adding the cost of any specialized tooling I may have to procure to do this) , or send it to you and have you beef it up? I'm not necessarily going for cheapest route, but want to get an idea of my options, so I can factor in my labor and see if it's worth doing myself, or if I should be leaving it to the pros.

The weird thing is, the breaks look clean, (unlike the ones shown in the links you just posted. The only place where it looks like a break occured is in the center of the spindle (1/2" dia.), the section around the center where the splines are cut looks machined, not broken. If it were not for the obvious metal shearing that took place in the middle, you'd think the spindles were machine that way, (makes me wonder if these were cheap rebuilds).

EDIT: So they sometimes "splice" these things together? THAT's what it looks like I've got, it's too clean to have been a complete shear. Why do they "splice"? Do they take spindles with damaged tips and cut them of and splice new ones on?

So, I'm hoping that the tips haven't done too much damage to the (rod that holds the spider gears...can't remember exactly what that's called).

Anyway, I think I have the mechanical apptitude to rebuild myself, I'll have to follow your threads.

The outer spindle bearings, seals, etc. all seem fine, although there is a little more play in the drivers side bearing than the passanger side, no play in the pinion shaft, and no excessive play between the gear and pinion, (as far as I can tell by just rotating the pinion shaft by hand)

What do you think I'm looking at money wise (ball park), for

a) minimal investment, just replacing broken spindles (hopefully nothing else is broken, but won't know until I pull the cover).

b) full blown heavy duty rebuild, including new clutch packs, new gear and pinion, HD spindles, etc.

Would it be cheaper to buy a complete unit from say Duntov, rebuild myself (adding the cost of any specialized tooling I may have to procure to do this) , or send it to you and have you beef it up? I'm not necessarily going for cheapest route, but want to get an idea of my options, so I can factor in my labor and see if it's worth doing myself, or if I should be leaving it to the pros.

21 - 40 of 42 Posts

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 2.2M

- members

- 122K

- Since

- 2003

A forum community dedicated to Corvette C Series owners and enthusiasts. Come join the discussion about performance, modifications, classifieds, troubleshooting, maintenance, and more!

Explore Our Forums