Been a month or 2 since my last post so here is what I've been doing. I have the seats, door panels, etc at the custom upholstery shop. Hopefully they will be done in 4 or 5 weeks. Meanwhile, one of my sons gave me a new 3D printer to mess with and it didn't take long to find something I needed to print. I have the optional manual control for the Dakota Digital gauge lights and since the knob looks a lot like a cig lighter I decided to make a mount for the control. That way I could use the existing hole where the cig lighter used to be. I drew up a 3D Cad drawing of the part I needed, sliced it and sent it to the printer. Worked perfectly, and I like the looks of the new knob. the pics below are the backside of the console bezel with the new mount bonded in place with ABS pipe cement. I got a little sloppy with the glue but it's on there for sure!

![]()

![]()

I ran new 2-0 battery cable from the back and originally had it connected to the starter solenoid like OEM. The solenoid terminal is also where the two fusible links tapped into power and fed it to the fusebox. The 2-0 cable is flexible enough but it starts getting very crowded in that area real quick. The LS doesn't have a whole lot of space right above the starter. So, after wrestling with it for day or so I decided to install a remote distribution block from CE Autoelectric. It is a 4 post rated at 350 amps continuous. I connected the 2-0 AWG main supply cable to the block, ran a 4 AWG over to the starter (only about 18 inches long) and a 6 AWG up to the GMPP fuse panel. Made things WAY easier.

![]()

![]()

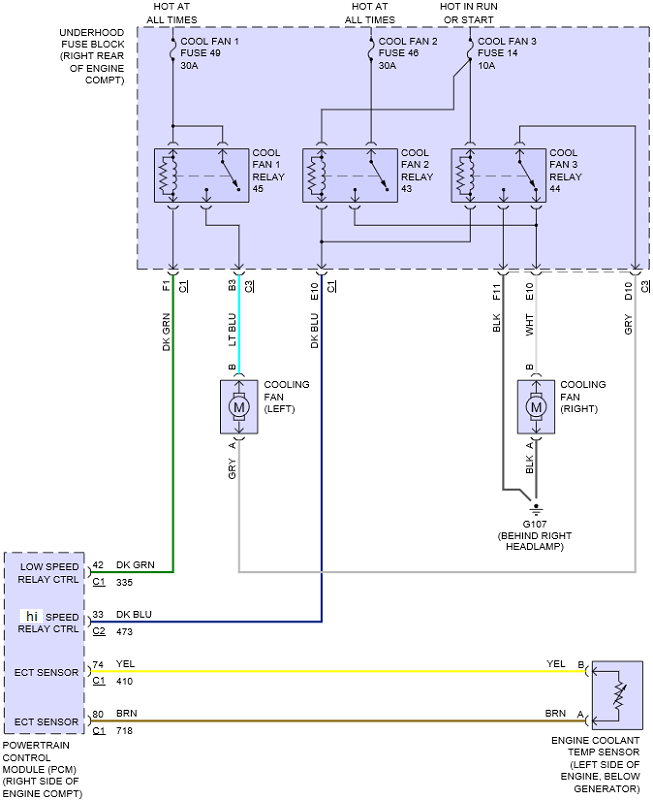

Here's a few things I learned about the GMPP Electrical Center (fuse/circuit breaker panel) that comes with the GM kit for the LS3. I didn't want to use a bunch of in-line fuses for the radiator fans as well as other devices when the Electrical Center was just right there. So I popped the panel out of the case and did a little research. This may be well known but I'll share what I learned anyway. The GMPP LS3 kit uses the Delphi 12146281 Electrical Center as the basis for the fuse panel. As delivered, the panel uses only 4 of the 10 Maxi Fuse sockets. But the other 6 Maxi Fuse sockets do not have terminals in them. Only 1 side is connected to the power bus. After some serious digging I found the necessary terminals in the Delphi Connection Systems catalog. For the Maxi Fuse terminal that fits 10 AWG wire, you need Delphi P/N 12110127. Different size wire uses different P/N terminals. They are listed in a table in the catalog so consult the catalog for different size wire. There are also quite a few of the smaller fuse sockets that are not used, and like the Maxi Fuse sockets, there is no terminal in the small sockets. Only the bus side has terminals. These terminals are Series 280. For size 10 AWG you need the 280 series, tangless, unsealed, 16.2 mm spacing terminals, Delphi P/N 12110647. Some of the Delphi Electrical Centers use 15 mm spacing so pay attention to the table in the catalog. The terminals also have different P/Ns for different wire sizes.

Anyway, after all that, the object was to have all fuses in the GMPP Fuse Panel instead of inline fuses all over the place. The inline fuses work, and I've used a bucketful of them over the years, but I didn't want that on this car. To buy the Delphi terminals you may find it hard to find a source that doesn't have a 2,000 piece minimum purchase, but a little sleuthing will find a source for small quantities. I found the Maxi Fuse terminal P/N 12110127 on Amazon, min quantity 5. I found the 280 series terminal P/N 12110647 on ebay, min quantity 10. As hard as they were to find, they are a piece of cake to crimp onto the wire. Expanding the Delphi Electrical Center is an easy, clean way to add circuits. I recommend downloading the Delphi Connection Systems.

Here is the 800 series Maxi Fuse terminal:

![]()

![]()

Here is the 280 series fuse terminal

![]()

![]()

Here is the GMPP fuse panel with 2 additional Maxi Fuses for the cooling fans

![]()

Getting late, more to come...